- Diy usb converter adapter code#

- Diy usb converter adapter download#

- Diy usb converter adapter free#

- Diy usb converter adapter windows#

So to work out what pause we needed for say 45IPM we would use 2250/45 which gives us 0050

This will differ depending on the Step Mode that the controller box is set to.įind some examples below, obviously we round up because we only send 4 digits to the controller.Ī 2250 Microsecond pause gives 25.4mm or 1 Inch Travel per minute.Ī 1125 Microsecond pause gives 50.8mm or 2 Inch Travel per minute.Ī 0562.5 Microsecond pause gives 101.6mm or 4 Inch Travel per minuteĪ 0281.25 Microsecond pause gives 203.2mm or 8 Inch Travel per minuteĪ 0140.625 Microsecond pause gives 406.4mm or 16 Inch Travel per minuteĪ 0070.3125 Microsecond pause gives 812.8mm or 32 Inch Travel per minuteĪ 0035.15625 Microsecond pause gives 1625.6mm or 64 Inch Travel per minuteĪ 0017.578125 Microsecond pause gives 3251.2mm or 128 Inch Travel per minute Same as the X-Axis but this time only 2 bytes(16bits)Ġ050 = Pulse delay in Microseconds for speed. The next 2 bytes control how many pulses you wish to send to the Z-Axis. The next 3 bytes control how many pulses you wish to send to the Y-Axis.

On our machine 533.333 pulses =1mm so to tell it to travel we first have to round up and break to binary int(533.333)=533īy doing it this way we can send a max 16777215 pulses which = 31457MM (103 feet!) Travel The next 3 bytes control how many pulses you wish to send to the X-Axis. This option takes more processing time, so speed pauses may have to be adjusted.īit4= Tells Firmware to ignore limit switches 1=ignore 0=do not ignore If you set it to 0 then it will move the X and Y axis at even pulses to get to it's destination giving the correct line needed. If you set this bit to 1 then the firmware will not care about how it gets to this position and it will just clock each Axis until it gets there. This first byte gets broken down into 8 bits and they do the following:īit3= Travel kind, this is for the firmware to tell it to use different routines for G00 travelling or G01 cutting, 1=Travelling 0=Cutting Type 1 is configured for the following Pin ConfiguratĪs we have said before, if you need the firmware customised to suit your controller then please email us and we will re-compile and release here. The fuses have all been set in the hex file, so simply load up, Program and Verify. You will need a suitable Pic Chip programmer that supports the 18F4550.

Diy usb converter adapter code#

This code is for use with the 18F4550 Pic Chip.

Diy usb converter adapter download#

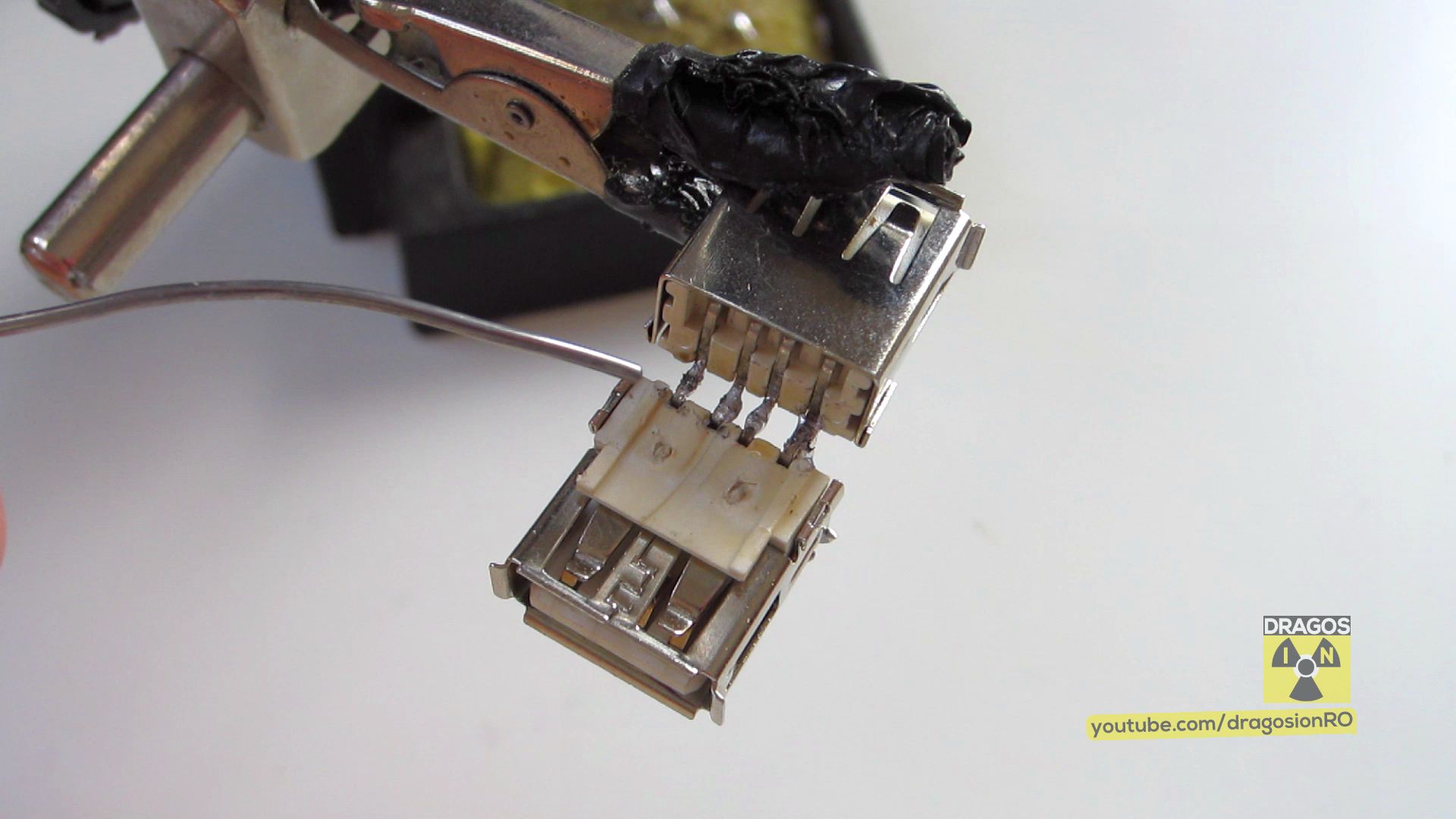

Inside this file are two Gcodes, one for the Milling and the other for the drilling.ġ * 20mhz Xtal (the Pic internally clocks this upto 48mhz)ġ * little tactile push switch for resetting Pic, not really needed.Ĭlick here to download the Firmware Version 1.2 Type1: usb-par-firmwarev12-type1.zip Milling PCB below with 0.2mm engraving bit.Ĭlick here to download the Gcodes: usb-par-gcodev1.zip We are also releasing the PCB Layout in Gcode for people wanting to mill their own. These are 600DPI JPG and need to be viewed and printed in Adobe Photoshop for an exact scale.Īlso included are postscript files as well. The reason this will work with any existing Controller box that uses the parallel port to control the Clock and Signal lines is because we will release standard Firmware that will cover different pin configurations as needed.įind below the first picture of version 1.0Īs you can see, this is not going to cost you a lot of money to make!!!!!!!!!Ĭlick here to download the Hi Resolution images: usb-par-hi-respcb600dpi.zip With this simple circuit and our Firmware you will be able to simply plug it into your existing Controller box and using our software, run your Gcode via the USB Port.

Diy usb converter adapter free#

To compliment our new FREE Beta USB Application (Shown Below) along with new Firmware, we are going to release a very simple circuit that people can build themselves that will let you control any parallel port stepper motor controller via USB. You just build it, use it and let us know of any improvements we can make.

Diy usb converter adapter windows#

We supply the PCB design FREE, the Firmware FREE and the Windows Application FREE Well now you can convert it to USB with this very simple Circuit below. Do you drive your Motor Controller usually via the Printer Port?

0 kommentar(er)

0 kommentar(er)